GAS SULFONATOR

SERIES SD-15

The SUPERIOR™ Series SD-15 Modular Automatic Switchover Gas Sulfonator is a state-of-the-art, totally vacuum-operated system designed to automatically switch sulfur dioxide feed from an empty cylinder to a full cylinder. The Series SD-15 allows round-the-clock Sulfonation without concern about running out of sulfur dioxide when the system is unattended. Series SD-15 Sulfonators are of the vacuum-operated, solution feed type designed to mount directly on sulfur dioxide cylinder valves. A vacuum-operated switchover module is mounted on the wall and connected to both sulfur dioxide vacuum regulators. A sulfur dioxide gas flow meter panel indicates the amount of sulfur dioxide being fed and may be located wherever it is safest and most convenient. Sulfur dioxide flow rate is manually adjusted, and the design permits easy addition of a number of automatic flow rate control devices. A high-efficiency, water-operated ejector produces the vacuum necessary to operate the system. The ejector assembly contains a back-flow check valve system to prevent pressurized water from entering the Sulfonator. A spring-opposed diaphragm vacuum regulator controls the sulfur dioxide gas flow rate and also acts as the safety shut-off valve.

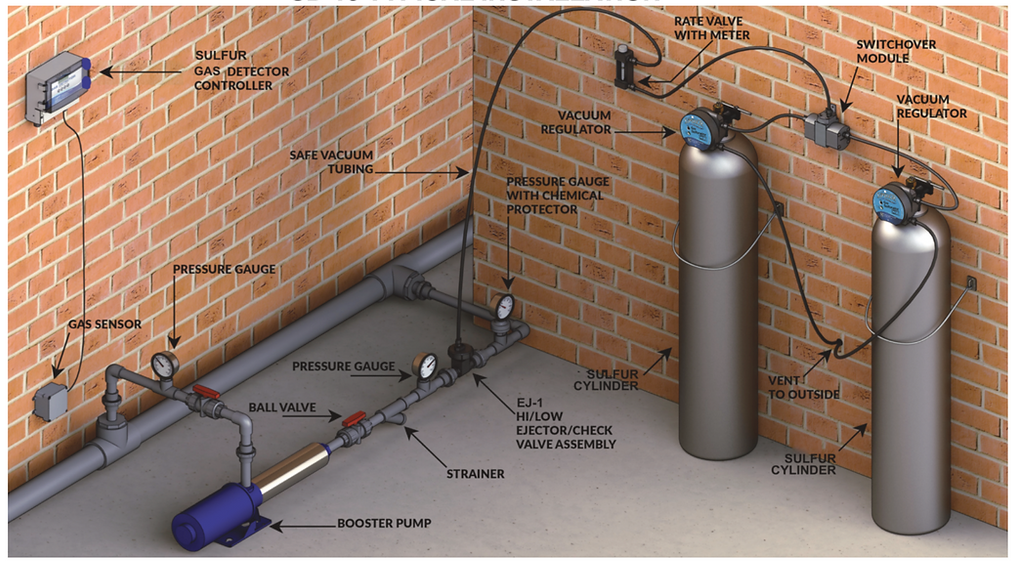

SD-15 TYPICAL INSTALLATION

FEATURES

The SUPERIOR™ Series SD-15 represents the most modern design technology coupled with the very best materials available to create an outstanding, user-friendly piece of equipment. It is designed with user safety as a primary concern.

-

A new ultra-thick, fluoroplastic yoke coating gives superior corrosion resistance—will not crack, peel, or chip.

-

All machined parts are high-impact PVC plastic, designed for superior strength, warp-resistance, and sulfur dioxide resistance.

-

The rate valve “Seat” is pure fluoroplastic and will not swell, stick, or become brittle with age or exposure to liquid sulfur dioxide.

-

All external bolts and nuts are Titanium for complete corrosion resistance… a SUPERIOR™ exclusive.

-

Extra heavy-duty outlet threads on the ejector diffuser prevent breakage from over-tightening or “bumping” of the ejector assembly.

-

Easier to service and perform routine maintenance, with standard size wrench lugs provided on all screwed-together ejector parts.

-

All vacuum fitting holes are heavily reinforced to prevent the possibility of cracking from over-tightening fittings.

-

A “Dual-pressure” check valve is standard on all SUPERIOR™ gas Sulfonators. Proven high back-pressure unitized check valve design protects against sudden surges up to 300 PSIG, while a spring-loaded diaphragm check provides positive shutoff even when there is no back-pressure to force the seat closed.

-

The Switchover Module has been totally re-designed to prevent sticking, misalignment, or wear on internal parts. Up to 20% fewer parts than other designs means greater reliability.

-

Automatic Reset – The SUPERIOR™ Modular Automatic Switchover Gas Sulfonator system requires no manual reset of the switchover module once the empty source is replaced with a new source.

-

Fewer parts, combined with superior materials and a superior design, gives you a superior gas Sulfonator.

SD-15 FLOW DIAGRAM

SYSTEM OPERATION

The vacuum regulators are securely clamped onto the sulfur dioxide cylinder valves. Vacuum tubing connects each regulator to the wall-mounted automatic switchover module. A single piece of vacuum tubing connects the outlet of the module to the wall-mounted remote meter tube/rate valve panel. The ejector is connected to the remote meter panel with a single piece of vacuum tubing. Water under pressure flows through the ejector at high velocity, causing a strong vacuum to be created. This opens the check valves in the ejector assembly and transmits a vacuum signal through the remote meter tube/rate valve panel, back to the vacuum regulators. When the vacuum reaches a pre-set level, the diaphragm in the regulator moves, opening the sulfur dioxide inlet safety valve, and permits gas to flow from the sulfur dioxide cylinder. The spring-opposed diaphragm and inlet valve regulate the vacuum at this point. Sulfur dioxide gas passes through the regulator, pressure relief valve connector, remote flow meter panel, and rate control valve to the ejector. The gas mixes with the ejector water and is discharged through the diffuser into the water being treated. When the sulfur dioxide supply is depleted in one source, vacuum starts to increase in the system, creating a differential across the diaphragm in the switchover module. This overcomes a spring-loaded toggle assembly, and the unit then switches over, permitting sulfur dioxide gas to flow from the full source.

FLOW METER CAPACITIES

SUPERIOR™’s modular design concept allows the sulfur dioxide gas indicating meter and flow rate control valve to be located wherever it is most convenient for the operator, and also in the safest location. Variable area flow metering tubes are available with dual English/Metric scale maximum capacities of 0.8, 1.5, 5, 10, 25, 50, and 100 pounds per 24 hours of sulfur dioxide gas, as well as 15, 30, 75, 200, 500, 1000, and 2000 grams per hour, respectively. All metering tubes are interchangeable and may be changed in the field without special tools.

MATERIALS OF CONSTRUCTION

One of SUPERIOR™’S major competitive advantages is the use of the finest, strongest, and most durable materials available. Extensive use of fluoroplastic and fiberglass-reinforced thermoplastics allows SUPERIOR™ Gas Sulfonators to withstand attack by sulfur dioxide in any form and to provide the longest operational life.

Many parts are guaranteed for the life of the equipment against sulfur dioxide damage.

SPECIFICATIONS

The Sulfonator shall be SUPERIORTM MODEL SD-15, manufactured by Chemical Injection Technologies, Inc., Ft. Pierce, Florida, and shall have a maximum capacity of ___ pounds per day /gr/hr of sulfur dioxide feed and shall be equipped with a sulfur dioxide flow meter of ___ pounds per day /gr/hr.

The Sulfonator shall be of modular design consisting of two (2) vacuum regulators, one (1) vacuum operated switchover module, one (1) flow meter/rate valve panel, and one (1) ejector/check valve. Each of these assemblies shall be capable of being individually located wherever safety and/or operator convenience dictates. The vacuum regulators shall mount directly on the sulfur dioxide cylinder valves by means of a positive yoke type clamp having an integral tightening screw with slide bar handle. No wrenches or other tools shall be required to mount or dismount the vacuum regulator from the sulfur dioxide valve. The sulfur dioxide valve/Sulfonator inlet adaptor shall be constructed of corrosion-proof fluoroplastic material which shall be inert to the effects of wet, dry, or liquid sulfur dioxide. The inlet safety shut-off/vacuum regulating valve shall be of capsulated design, easily removable as a unit from the outlet side of the yoke.

A ceramic filter shall be installed in the vacuum regulator inlet and shall be capable of removing impurities greater than 25 microns. All external screws and nuts shall be made of Titanium to prevent corrosion.

The switchover module shall be vacuum operated and shall be factory pre-set, not requiring field adjustment. The module shall automatically change sulfur dioxide feed from an empty sulfur dioxide source to a full source, with no manual resetting required after switchover has been made and the empty supply replaced.

The vacuum regulator/flow meter bodies shall be constructed of high-impact PVC plastic material and shall incorporate a flow rate control valve made of fluoroplastic material which is inert to the corrosive effects of sulfur dioxide. The rate valve metering tip shall be constructed of metal which is completely impervious to the effects of wet, dry, or liquid sulfur dioxide attack. Design shall provide for full closing of the rate valve without engaging the control surfaces, to prevent damage. Vacuum shall be created by a fixed-throat venturi/ejector system connected directly to the sulfur dioxide solution diffuser. A dual high-pressure/low-pressure check valve system shall prevent water from entering the gas system.

The ejector assembly shall be capable of withstanding water pressure up to 300 PSIG (20.7 Bars). A universal-type sulfur dioxide solution diffuser shall be provided which shall allow close-coupling of the ejector to a water main, use of flexible solution hose, or rigid solution pipe without the use of special adaptors.

SPECIFICATIONS

STANDARD ACCESSORIES

50 ft - Vent & Vacuum tubing

20 - Lead Cylinder Connection Gaskets

1 - Cylinder Wrench

1 - Vent insect screen

OPTIONAL

ACCESSORIES AVAILABLE

Inlet Water Assembly

Gas Masks

Wall Manifold Kits

Gas Detectors

Booster Pumps

Scales

Residual Analyzers

Gauges

Automatic Controls

Sulfur Dioxide Comparators

Ton Container Adaptors

OTHER SUPERIOR™

SYSTEMS AVAILABLE

MULTIPLE-POINT GAS CHLORINATORS

250 POUNDS PER DAY (5 KG/HR)

500 POUNDS PER DAY (10 KG/HR)

GAS CHLORINATORS

AMMONIATORS

AUTOMATIC FLOW PROPORTIONING

AUTOMATIC RESIDUAL CONTROL

SUPERIOR™ Gas Chlorinators are proudly made by Chemical Injection Technologies, Inc.

835 Edwards Road, Fort Pierce, Florida 34982 USA. T: 772-461-0666.